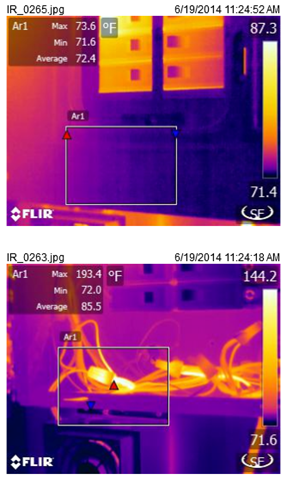

One of my personal favorites is a simple mock-up of an electrical panel rigged with several thermal anomalies on the inside. Warm breakers, hot connections and more can all be safely inspected in this controlled environment. I use this particular lab in Level I training to demonstrate the concept of indirect heating that we teach as a part of basic heat transfer. This is the physics behind why the temperature you measure on the surface of a component is often much cooler than what is happening on the inside, at the point of failure.

Upon opening the cover, several additional thermal anomalies are revealed to the student, one of which is significantly warmer than the hottest spot detected with the cover closed. At an apparent temperature of about 193˚F (89˚C) this connection problem is now obvious, however, it was undetectable in the original thermal image with the panel shut.

This example immediately disproves the myth that you do not need to remove electrical covers to conduct a thorough infrared inspection. As thermographers we need direct line of sight to get the most accurate assessment of a problem. Now doing so in the real world introduces a number of other issues which need to be properly addressed including safety. Of course the only people who should be opening electrical panels are qualified electricians wearing the right category of PPE. This particular lab, however, provides all thermographers with a safe opportunity to see firsthand how much they are potentially missing should a similar situation of indirect heating be encountered in the field.