Process Heaters

There are as many uses for process heaters as there are designs. The basic configuration consists of a shell (outer casing), tubes (where the process fluid flows) and a heat source. These units are both thermodynamically and hydraulically complex.

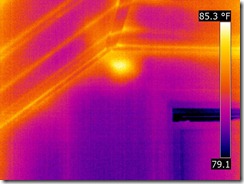

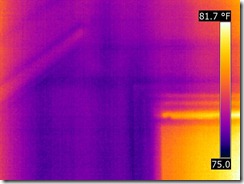

The simple drawing illustrates convective gas flow, which is turbulent, and radiant heat from the flame, refractory and other tubes – all non-uniform and time varying. When you view tube from an access port typically you can only see a portion of the tube or the tube at an oblique angle. Sometimes tubes are in rows, difficult if not impossible to image.

Why are heater tubes of interest anyway?

|

| Tubes in a fired heater |

Sample Thermal Images

|

| Tube with restricted flow |

|

| Coking on bottom of tube |

IR offers the operators of process heaters the ability to visualize the heat transfer and provide vital temperature data to help determine remaining tube life. Certification training from the Infrared Training Center (http://www.infraredtraining.com) teaches you the techniques required to successfully implement this technology at your facility.

Thermography Certification Dates and Locations

- Training Dates and Locations in the US and Canada: http://www.infraredtraining.com/schedule

- Training Dates and Locations in Europe, Middle East and Africa: http://www.irtraining.eu

To learn more about these certification classes, as well as upcoming training dates and locations, please visit the Infrared Training Center online at http://www.infraredtraining.com